Click to enlarge

Your Home Bicycle Workshop

by Jim Langley

Everything you need to know to build

a great home bicycle workshop!

Click pictures to learn more

My truing stand

More truing stands & wheel

tools

Eldi emergency spoke tool

Eldi Emergency Spoke Bicycle Tool

A Spoke Recycler

The great thing about this bicycle spoke cutter and

bender is that it allows a mechanic equipped with a handful of long

spokes to fix bicycle wheels of any size. How? The tool shears the

head off the spoke. Then, by holding the spoke just so in the tool’s

jaws and squeezing the handles, an S shape is bent into the spoke’s

end as shown. Because you can put this shape anywhere along the spoke’s

length, you can size long spokes to fit every size wheel.

A Ride Mechanic’s Treasure

This spoke shaper is the perfect tool when you’re

wrenching for a ride or race. Instead of carrying several common spoke

lengths for repairs, simply pack a supply of long spokes and you’ll

be prepared to repair any wheel that needs help. It came in very handy

one year when I was manning a century rest stop in Paso Robles, California

during the Great

Western Bike Rally. Early in the day, I repaired a 700c wheel

and in the afternoon, a couple came through on a Bike Friday Family

Tandem with 20-inch wheels. I used the Eldi to size spokes to fit

and saved three riders from having to SAG in.

A Ridesaver

Bicycle spokes with this S bend are known by tourists

as emergency spokes because the special bend simplifies installation.

Carry some emergency spokes inside a pump, handlebar or bag and should

you break a spoke, simply wiggle it out of the hub and you’ll

be able to poke the emergency spoke’s S-shaped head in its place.

You won’t have to remove the wheel, cassette, tire, tube or

nipple (assuming you were smart enough to prepare emergency spokes

that match the nipples in the wheel). So, these spokes come in very

handy. And, they’re strong, too. I’ve ridden for years

on one with no problems.

A Keeper

I’ve searched for this tool without luck so

I don’t believe it’s available any longer. It’s

possible to create emergency spokes by cutting the heads off with

diagonal cutters and bending the S with pliers. But, that’s

a crude way to go compared to Eldi’s solution.

Update on finding a tool that can

create the bend: The wonderful wheel resource Wheel Fanatyk now offers

their Z-bend

Spoke Repair Pliers. Also, ace mechanic Roger at PacTour

told me about a tool for lawnmower throttle cables that can do this.

It should be available at lawn-care stores.

Shimano Pro-Set HG chain cutter

Shimano Pro-Set HG Bicycle Chain Cutter

Almost Too Nice to Use

This photo depicts my prize bicycle chain tool just

about life size. Put your hand up to the photo and you can imagine

using it. The handles are rosewood and wonderfully smooth. You might

not think it would make a difference when working on grimy links,

but I swear it makes the job easier. It’s not so much the quality

of the wood perhaps, but the size of the handles. A nice detail is

a small screw on the bottom of the handle that when removed, reveals

two Hyperglide chain pins stored inside. The tool’s pin is easily

replaced too, of course.

I Earned It

I favor this fine chain tool (and I’ve got about

a half dozen different types) but it’s special for another reason:

the way I got it. It was gift from Shimano for working as a mechanic

on their neutral support team during the Mountain Bike World Championships

in 1995. Every time I pick up this beauty it reminds me of that great

week in Vail, Colorado.

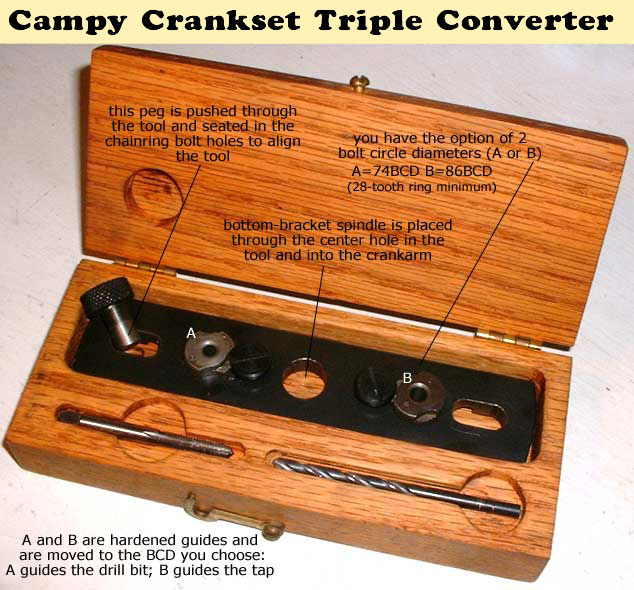

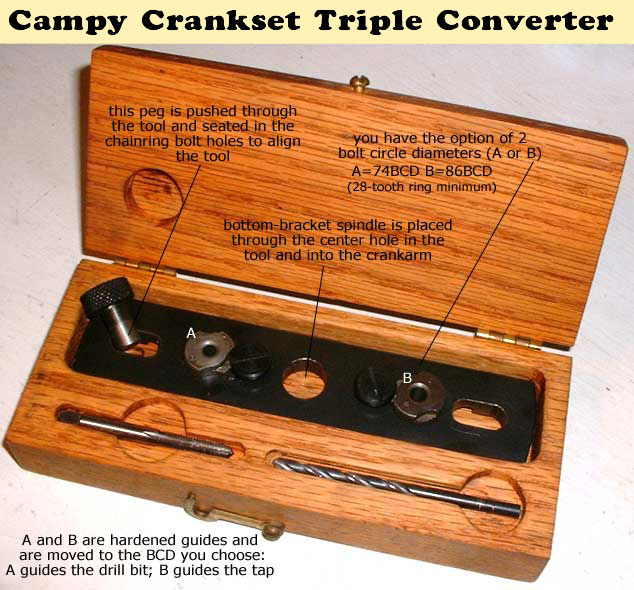

Custom classic Campy triple tool

This is an unusual and rare bicycle tool made by a

machinist in Southern California and sold in the early eighties to

bicycle shops who used it to convert Campagnolo Nuovo Record and Super

Record double cranksets into triples (the smallest chainring these

accept is 41-tooth; not very small).

The jig is held in place by the bottom bracket axle

and you can then accurately drill and tap 5 holes in the spider. Into

these holes you insert Avocet/Ofmega triple-conversion adapter bolts.

These are steel and are mounted to the spider with locktite if the

crank will remain a triple. The adapters have female threading on

the backside to accept standard chainring bolts. To install the granny

ring, you simply rest it atop the Avocet/Ofmega adapters, screw in

the chainring bolts and easy pedaling is yours!

I recently found a new home for this tool with a bicycle

club that has several Campy-equipped classic bicycles in need of triple

conversions.

My toolboard

Click to enlarge even more!

Toolboards are personal things. Mine reflects the

bicycles I maintain, the tools I like most and a design that works

for me and my workshop. I try to place the most frequently used tools

closest and design the board so that the tools are within easy reach.

I don’t want to have to move too far from the bicycle repair

stand or stand on my toes to reach a tool. I also don’t want

too many tools on my board because it only spreads the tools further

apart and makes it more difficult to find tools, which slows you down.

I keep my cutting and milling tools in drawers to protect the sharp

edges, and also because they’re not used as often as the basic

hand tools, so it’s no biggie to open a drawer to get them.

I’ve used finishing nails in the past for my

toolboards and they work fine. This time I tried something different,

little

screw-in ball-end stainless-steel hooks. It’s not as easy

to get the tools off them, but they sure look nice and I think I won’t

mind taking a little more care when reaching for tools. This is a

new plier tools arrangement for me, too. I typically mount each plier

tool to the board separately; however, this new approach makes them

much more accessible because one handle is free and easy to grab.

The 2 x 4 rack also provides a superior way to hold the ratchet, 8mm

Allen and tape measure (it’s missing from the photo; it clips

to the Atala headlight bracket).

A good way to make your own toolboard is to pick up

a bike box at a shop. Cut one side off it and lay it on the ground.

Take all the tools you want on your finished toolboard and lay them

out carefully on the cardboard. Move them around until you have them

just the way you want them. Then you can trace around them with a

Sharpie marker. You now have a handy template, which you can hold

against your plywood. Simply drive nails through the tracings right

where the nails will support the tools, pull the template off and

hang your tools. Have fun!

Oh, if you’re wondering, those three small ratchets

on the right 2 x 4 hold a 4, 5 and 6mm Allen wrench. The little gizmo

protruding to the left of them is a combination magnet/screw holder

and the T-shaped item left of the yellow screwdriver is a valve tool.

Finally, people ask why I don’t outline my tools

on the toolboard. This is a common technique in shops where many people

use the toolboards. It helps at the end of the day when you want to

do a quick inventory and make sure every tool is back in place and

it helps non-mechanics put the tools back in the right place. In a

home shop, you get used to where your tools belong and you don’t

really need to outline them. Also, not having outlines is good motivation

to return the tools as you work, which keeps your workbench clean

and makes it easier to find the tools when you need them. Quick tip:

if you look high and low and simply can’t find the tool, check

your apron pocket. Without tool outlines, toolboards look cleaner,

too, and I like that. It’s the same reason I don’t use

pegboard for my toolboard. I find all those holes distracting compared

to simple plywood.

On this

webpage you can see pictures of the beautiful toolboard of world-renowned

professional mechanic Pietro Piazzalunga (and read a fascinating interview

with him, too).

Bicycles are easy and fun to fix. Everything’s

right there, easy to see and figure out. With basic hand tools, you

can make many common repairs. Just by riding, you can diagnose problems.

And even advanced bicycle repair such as wheelbuilding

is within your reach . . . (more)

In fact, it was the friendliness of bikes that got me

into bicycle mechanics in 1972. At my first job, I was so taken with

wrenching that I dreamt of bike tools

at night, and got to work in the morning an hour early, eager to get

back behind that repair

stand and start assembling and tuning two-wheelers. I stuck

with it for seventeen years and worked in six shops, from New Hampshire

to California.

Then, one day, while working at the Bicycle Center in

Santa Cruz, California, I got an offer to write for a new magazine

out of San Francisco, called California Bicyclist, and I began

writing a monthly column called “Technicalities.” This

led to freelance work with Velo News and Bicycling Magazine.

And in 1989, when Bicycling decided to open the company’s

first satellite office, they asked me to manage it. That’s when

I stopped wrenching full time and began writing.

I was Bicycling’s Technical Editor for

ten years, during which time I wrote about all of cycling. Perhaps

most useful and popular was my how-to series called “Repair

Stand,” in which I explained mechanical procedures step-by-step.

These proved popular enough that there were reports of people

cutting them out of library copies of the magazine. And, much of the

information, along with the photo-and-caption format was used in creating

the best-seller Bicycling

Magazine’s Complete Guide to Bicycle Maintenance and Repair,

which I co-authored. My new book is Your

Home Bicycle Workshop, which is available

here.

Here are articles that’ll help you achieve

your wrenching needs and goals. Maybe you’ll even become

a pro mechanic (a great

occupation, because you can get a job anywhere, and every repair

is different; be sure to read my story about wrenching

at the world championships)! Plus, you too might land a gig as a cycling

journalist (read my weekly Tech

Talk column).

If you'd like say thanks for helping with your bicycle

repair or help me keep this site going, this button takes you to PayPal

where you can make a secure donation of any amount. Thanks!

Twenty-five Repair Articles (some with videos)

Click the 1938 bicycle wrenches

to see the articles:

If you'd like to say thanks for helping with your

bicycle repair or help me keep this site going, you can now donate using

this PayPal button. Thanks!

Videos open in a new window on my youtube channel.

Quick Repair Tips

For more excellent bicycle-repair help, visit:

![]()

![]()

![]()

![]()

![]()